Our Technology

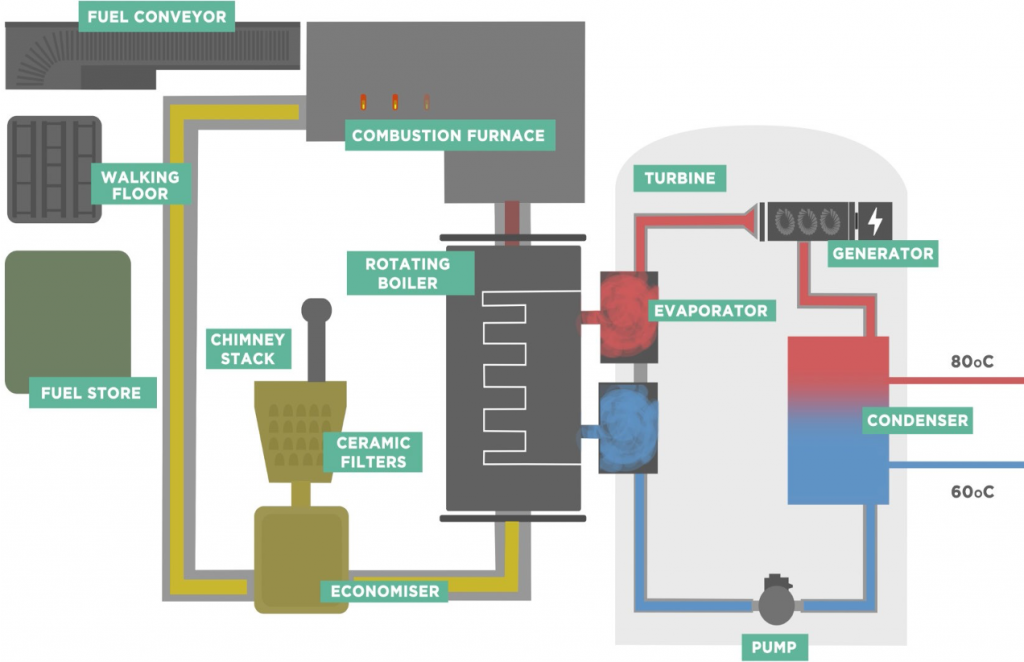

- The system will consist of a feeding system composed of a walking floor and conveyor, which will guarantee simplicity of operation.

- The combustion system will consist of a refractory brick chamber with high alumina content, which will contain a cast steel reciprocating grate system with high chrome content. This combustion chamber will be specially designed to work with RDF.

- Start up with natural gas burner

- 2-second gas permanence above 850ºC

- SNCR system for reducing NOx emissions by injecting urea solution into water.

- Combustion control by means of artificial vision system

- Retractable probe systems for temperature control at critical points.

- The gases coming from this combustion chamber will be introduced into a thermal oil boiler, the output gases from this boiler will be introduced into an SPLIT (thermal oil economizer) for increasing the overall efficiency, thus obtaining a power output per line in thermal oil to be used to feed an ORC turbine, thus producing a net electrical power at the ORC equipment terminals.

- In order to comply with the parameters that would be applied in the case of larger plants despite not being applicable, the following technologies will be used in the gas circuit:

- Sodium bicarbonate additive system for the reduction of acidic components in the gases

- Activated carbon additive system for VOC reduction

- Ceramic filter that will act as an additive reactor and reduce the particles emitted below 5 mg/m3N @ 6% O2

- Finally, to control emissions, a Continuous Emissions Monitoring System (CEMS) will be installed in the chimney to continuously monitor O2, CO, NOX, SO2, HCl, dust and TOC.

- The system is a flexible system that can be adapted to meet any change in the waste market conditions that would result in a change of the feedstock characteristics.

CARBON CAPTURE

Through our partnership with technology partner, carbon capture unit is available for installation to our systems. The benefits of the MHI system:

- Advanced energy saving process – significant operation cost saving

- Highly efficient proprietary solvent (KS-1™), with the lowest energy consumption and the least degradation

- This process can recover more than 90% of the CO₂

- It also reduces steam consumption thanks to our original energy-saving regeneration system